|

Navigation

Search

|

Why the iPhone Air’s USB-C port is actually a technical marvel

Friday November 28, 2025. 11:30 AM , from Mac 911

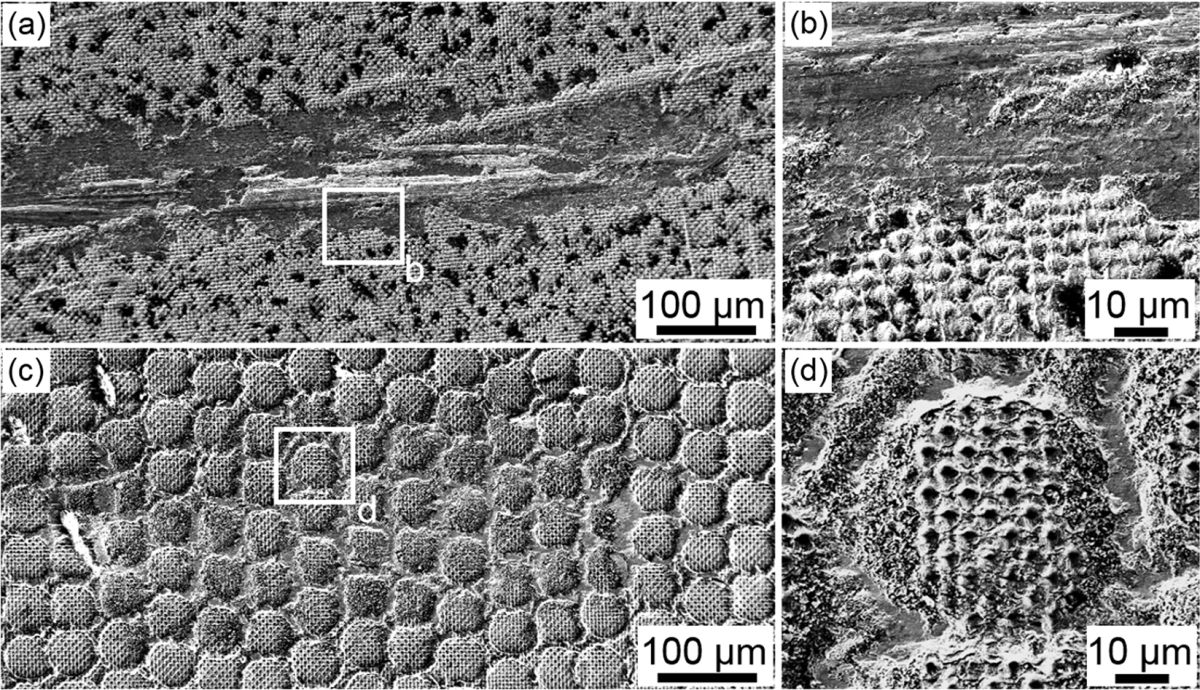

When Apple was still in the Lightning era and fought tooth and nail against USB-C, the common argument was that Lightning ports were significantly thinner than their USB-C alternatives. The USB-C connector is 1.1 mm thicker than Lightning (2.8 mm versus 1.7 mm). About five years later, Apple released its thinnest iPhone–with a USB-C port. If you place the iPhone Air next to any other USB-C smartphone and compare their ports, you will notice that the port on the Air is so incredibly thin that you can barely see its casing. This special feature is due to a new manufacturing process that Apple details in a recent press release, and which the repair specialist iFixit scrutinizes. How Apple manufactures the iPhone Air’s USB-C port Apple uses a new manufacturing process for the Apple Watch Ultra 3 and the iPhone Air. The housing of the Apple Watch Ultra and the port of the iPhone Air are 3D printed from a titanium powder. It was assumed that Apple would rely on the common method and mix the recovered titanium powder with an adhesive in order to “cast” the desired mold from this mass, layer by layer. However, as Apple shows in its press release and iFixit confirms with the microscope images, the company uses a 3D process with a laser. The desired molds are milled from a titanium block. The process was developed at the TU Dresden, the Fraunhofer Institute for Material and Beam Technology in Dresden, and the Leibniz Institute of Polymer Research Dresden, and was presented six years ago in the scientific journal Nature. The process was originally developed for titanium dental implants, which adhere better to the jawbone and are bacteria-repellent thanks to the special structure of larger craters (50 µm) and smaller holes of 5 µm on the crater surface. The laser-structured surface of a titanium implant.Nature / Fabrication of multifunctional titanium surfaces by producing hierarchical surface patterns using laser based ablation methods Benefits of the new process for the iPhone Air The new titanium surface of the Apple Watch Ultra 3 and the iPhone Air is not bacteria-repellent, but the structure still lacks the smaller 5 µm indentations that prevent the adhesion of slightly larger bacteria. However, the new components have other functions: the titanium produced in this way is more heat-resistant, which will particularly benefit the iPhone Air, as the device is charged via the USB-C port. With the Apple Watch Ultra 3, Apple points out that the watch has become more water-resistant. The new process allows for different structures in areas that previously had to remain flat. For example, the new housing has been given a rough surface around the frame so that the antenna adheres better to it. It can be assumed that the USB-C port of the iPhone Air also has this feature. The new process is energy-efficient and will save the manufacturer 400 metric tons of titanium by the end of the year. Around 50 percent less raw materials are used in production than in previous generations. The fact that Apple was able to shrink the iPhone Air to such an extent is due in part to the innovative process used to manufacture the USB-C port from titanium. This has made the component thinner, more heat-resistant, and more energy-efficient in production. Apple iPhone Air (2025) Read our review

https://www.macworld.com/article/2980105/iphone-air-usbc-port-technical-marvel.html

Related News |

46 sources

Current Date

Dec, Fri 19 - 01:55 CET

|

MacMusic |

PcMusic |

440 Software |

440 Forums |

440TV |

Zicos

MacMusic |

PcMusic |

440 Software |

440 Forums |

440TV |

Zicos